THE MAKING OF THE CUBE

Exterior Renovations

[above] Dan and Little Man relax after completing a bench on the the South side of the Cube. From 2021 to 2023 the entire exterior of the building was fitted with horizontal 1 x 6 cedar fence boards that were brought down in multiple truckloads from America

[above] As new plywood panels were added or replaced the building began to display a jarring pattern of random tones and textures. Staining only made matters worse. The linked slideshow tells the story of the re-cladding process over a period of just over a year

[above] The Del Mar city hall has exterior walls made of horizontal boards arranged in vertical panels. This detail seems in keeping with the modular panels of the Cube

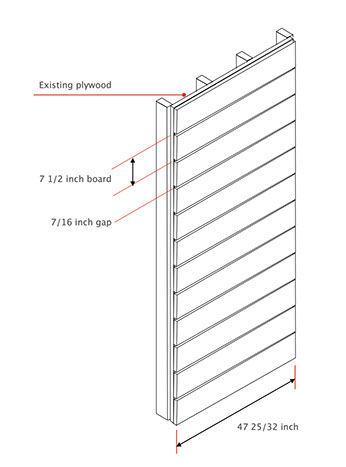

[left] A drawing showing how the 1 x 6 cedar could be applied over the 4 foot x 8 foot plywood panels of the Cube walls

[below, left] When the cedar boards were first applied, variations in color were quite noticeable, but after a few months of exposure to the sun [right] the variations disappeared and the wood took on an attractive even golden tone

Cedar cladding By 2020 the plywood exterior of the Cube was beginning to show signs of deterioration. What was once an innovative aesthetic—using a construction material as a final surface—had become a problem.

Our first thought was to stain the existing plywood and replace damaged panels with new ones that had also been pre-stained. The problem with this approach was that weathered panels that were stained had a markedly different color from the new ones, resulting in a discordant mosaic.

The solution was to leave all the plywood alone and cover the exterior with horizontal cedar fencing.

Cedar fencing usually comes in 6 foot lengths with a "dog ear" bevel on one end. Our truck has a 6 foot bed, but with the bed liner and the tailgate only 5 foot 11 inches of free space is available. Once the unneeded dog ears were chopped off the board fitted nicely down in the truck bed, invisible to the border guards.

Setting up the first row of board was critical. My old friend Jerry was on hand to work out the vertical spacing that needed to be maintained on all the walls of the building. Once the first plywood panel at the Southwest corner of the building was fitted with cedar we made a wood shim to keep the vertical spacing consistent with a 3/8 inch gap.

The cladding took place from September 2022 to November 2023 beginning on the South elevation and proceeding to the West side where Dan took over the work, and on a later trip he finished the North side. Jerry and I finished the East side in May of 2023. And in September of that year, our son Seth lent a hand to apply the cedar to the shed.

[left] The shed received the same horizontal cedar cladding as the Cube itself, but the boards were fitted in random lengths, rather than following the panel breaks of the underlying plywood

[below] Being tall, Seth had the honor of applying the last cedar to the East gable of the shed

Repairing and improving the North porch During 2023 we realized that the deteriorating north porch canopy, made of 1 x 4 slats, could be replaced with sturdier lumber and could also serve as an outdoor sleeping platform. The supporting beams and posts also need upgrading. A load of 2 x 4s from The Home Depot in Mexicali was brought down and installed to replace the old slats, which were set aside for making outdoor sculptures. We also made a hatch and built a ladder for access to match the spacing of the cedar siding.

Building the world's smallest bathroom The Cube bathroom creates a problem when people sleeping downstairs and outside need to use it when people are sleeping upstairs. The small hutch on the South side of the building measures just four feet by two feet and was originally built to conceal the drain from the upstairs toilet where it emerges from the wall. It turned out to be just big enough for an outdoor flush toilet.

[above] The Cube outdoor bathroom includes a light fixture and a shelf. The door has spring loaded hinges and locks from the inside. The blue pipe provides water from the roof tank. Hand washing is achieved by using the outdoor shower fixture seen at the right

[above] The North porch renovation includes a sleeping platform, a hatch, and a ladder to provide access. The location is secure from the scorpions and rattlesnakes that inhabit the dunes, and is ideal for overnight stargazing. The linked slideshow documents the construction process