CUBE SYSTEMS

Electricity

The solar system The story of the Cube's photovotaic system is a multiple decade quest to attain a balance between supply and demand. When we started out nobody could tell us exactly how many panels and batteries were needed. Over a period of ten years and more we eventually found out what worked and what did not work. Simply adding more panels to the system did not in itself attain equilibrium: it became clear that the rapid deterioration of the original lead-acid battery bank was the main culprit. Sophisticated charge controllers that stored excess energy from the panels in copper coils would break down and a pricey wind turbine's performance proved disappointing. Low maintenance and rugged simplicity, we discovered, were the keys to success.

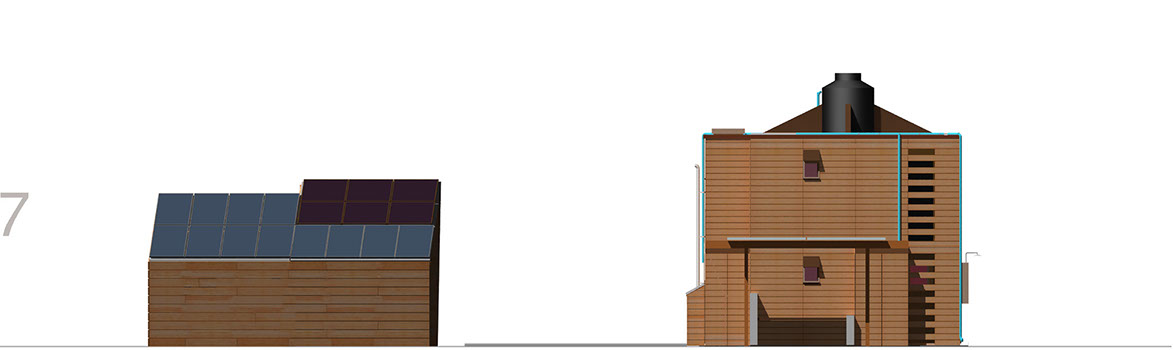

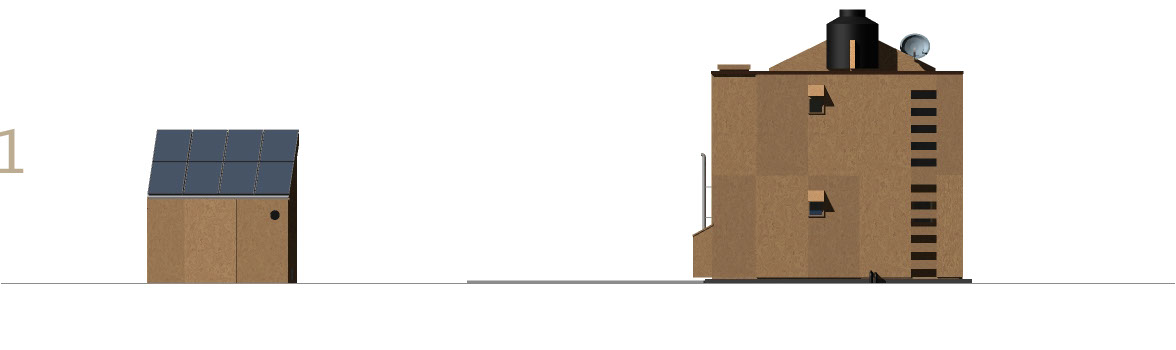

Solar phases The Cube’s original photovoltaic system consisted of eight panels and eight batteries. Eight panels happened to fit the roof of the shed whose size was determined by the existing concrete slab [Phase 1].

This system proved capable of powering the construction of the Cube, which took place in daylight, but in anticipation of the power requirement of a refrigerator we added four more panels and eight more batteries and a more powerful inverter [Phase 2].

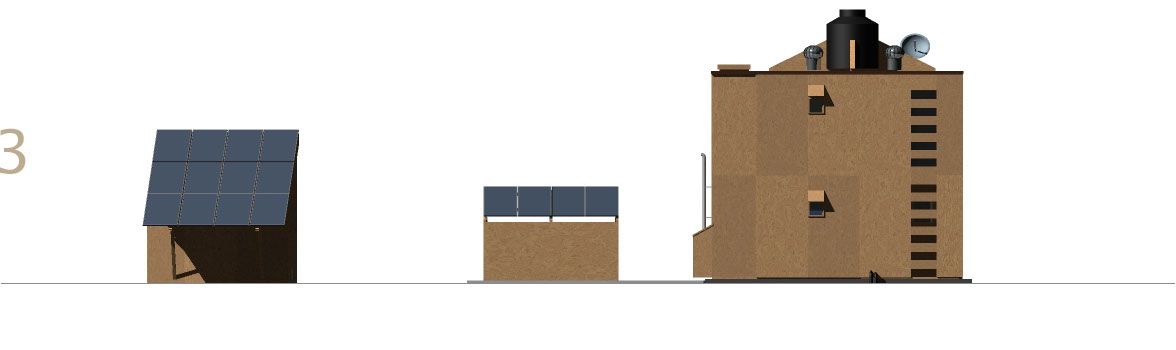

Unfortunately, all this turned out to be inadequate to support the fridge and overnight electrical use once the Cube was lived in. So four more panels were added on a separate structure [Phase 3].

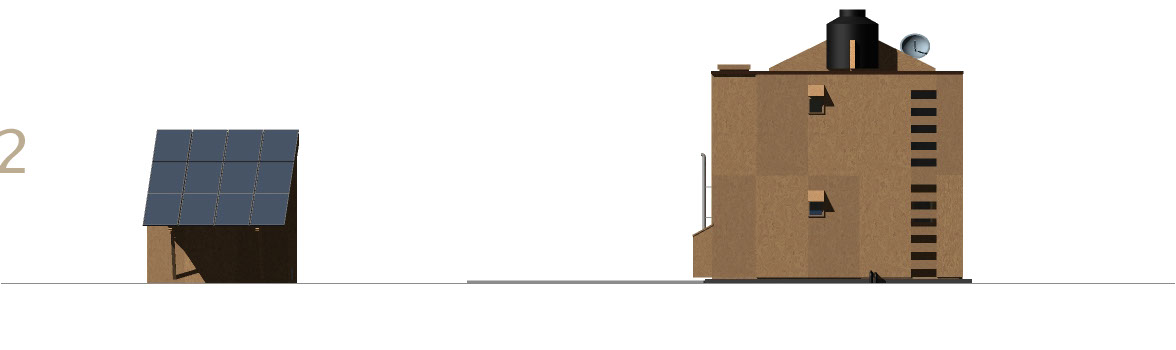

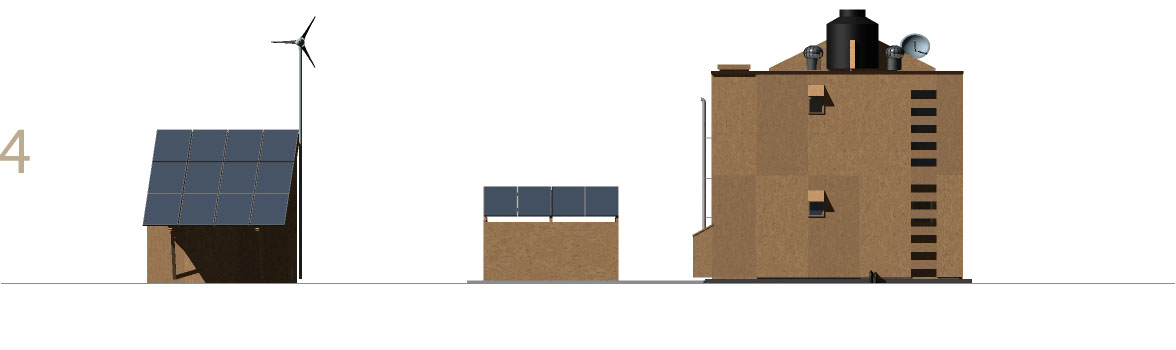

Nevertheless, problems in meeting power needs persisted. So a new charge controller was installed (the old one has begun to melt) and a wind generator was added [Phase 4].

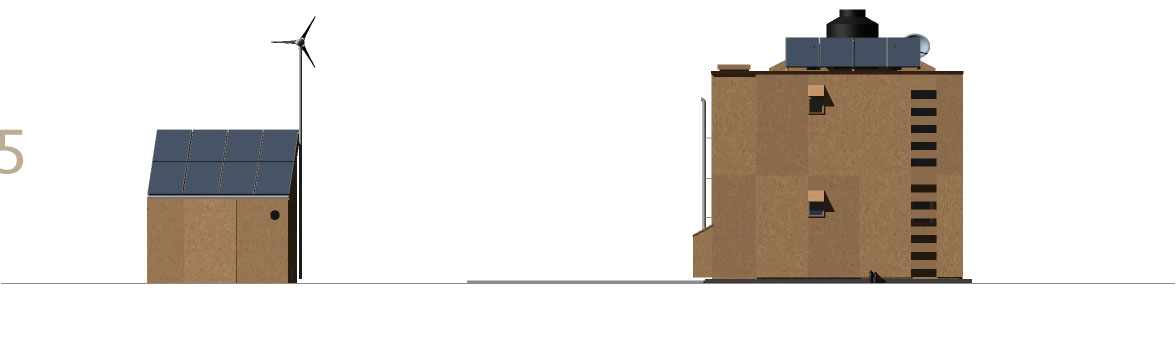

When the panels attached to the lower roof-line of the shed were stolen the remaining four panels on the separate structure were moved up to the Cube roof as a precaution. Meanwhile the lead acid batteries had begun to deteriorate and the terminals had become badly corroded [Phase 5].

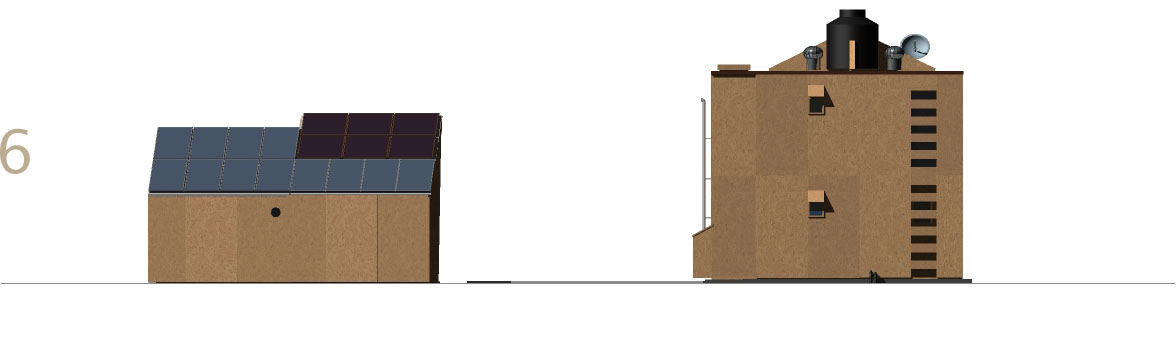

By doubling the size of the shed we were able to add six more panels. The Unisolar panels were now unobtainable so we substituted inexpensive Kaneka panels. The 16 golf cart batteries were all replaced with 8 12 volt gel batteries and the wind generator, which could only contribute an insignificant 2 amps at maximum power (while making an annoying whir) was decommissioned [Phase 6].

When we built an outdoor kitchen in 2023 we mounted four Yingli 260W panels on the shade structure above. A new charge controller and a 3000W inverter was added to take advantage of the extra power input. [Phase 7].

Phase 1 Eight Unisolar 64 watt panels at $290 each, eight deep cycle Trojan T105 6 volt golf cart batteries at $60 each, a UPG 1300 watt inverter and a 600 watt Blue Sky SB50 charge controller for $400

Phase 2 Four additional Unisolar 64 watt panels, eight additional deep cycle Trojan T105 6 volt golf cart batteries

Phase 3 Another four Unisolar 64 panels mounted on a free-standing structure, a BZ MPPT 500 watt charge controller replacing the SB50, and a Xantrex 2500 watt inverter replacing the UPG inverter

Phase 4 An Air X 403 wind turbine rated at 500 watts and costing $800 installed, and a replacement Trace T40 Charge controller. The stolen inverter was replaced with an identical model

Phase 5 Four Unisolar 64 watt panels moved to the Cube roof after four on the shed were stolen

Phase 6 Six Kaneka 55W panels at $172 each installed on enlarged shed, the Unisolar panels moved down from the Cube roof to the shed roof, eight Deka 12v gel batteries replace the golf cart batteries at $530 each

Phase 7 Four Yingli 260W panels at $80 each mounted on outdoor kitchen pergola structure.

A new OOYCYOO MPPT charge controller was added but the original Trace T40 was retained. A Xantrex Fredom XC Pro 3000W inverter, was added in to handle the increased power

ROLLOVER DOTS TO VIEW PHASES

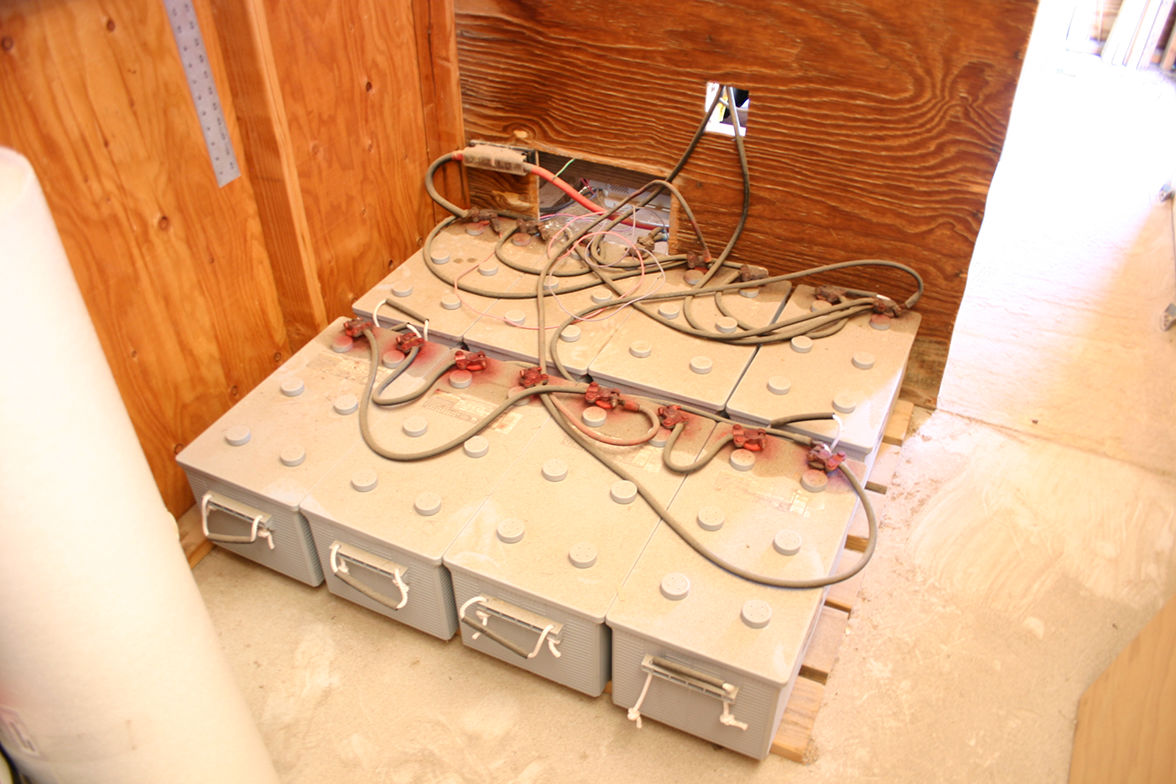

[above] The Cube's lead-acid battery bank from Phase 2. [middle] By Phase 3 serious corrosion has taken hold and battery performance is marginal [below] Expensive but worth it, gel batteries now provide plenty of overnight power and show no signs of corrosion so far

Powering the Cube Here is a summary of the overall electrical system for the Cube. The power source is a combination of twelve 64 watt photovoltaic panels, six 55 watt panels, and four 260 watt panels wired together at 24 volts DC. Feed from the panels is collected via bus bars and connected to two charge controllers. The charge controllers regulate the DC feed to the battery bank and shut down when the batteries are full. The battery bank consists of eight 12 volt gel batteries wired in series and in parallel to give 24 volts output. The Inverter takes the DC feed from the batteries and converts it to AC, using a pure sine wave. A separate DC 12 volt circuit feeds power from one of the batteries directly to a DC water pump above the Cube bathroom sink. The AC output from the inverter travels via underground conduit to the circuit breaker panel at the foot of the Cube stairwell. All light fixtures and plugs in the Cube derive their power from this panel. Another underground cable from the shed supplies power for lights and plugs in the outdoor kitchen.